|

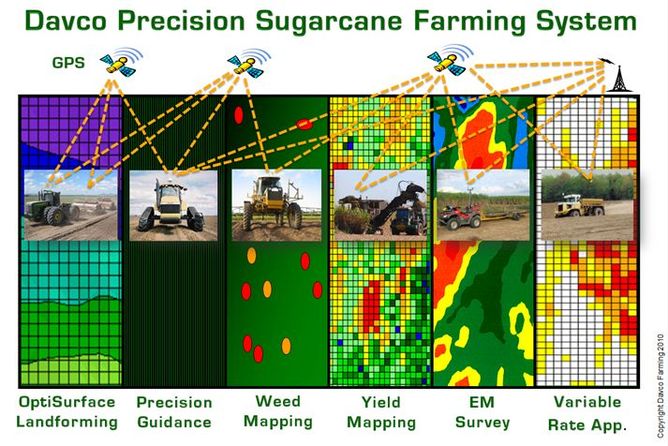

The Davco Precision Sugarcane Farming System

DAVCO Farming has developed a unique and innovative sugarcane farming system that integrates a number of world leading technologies. An overview of this system is provided below. The system incorporates the following practices:

The major factors driving the adoption of precision agriculture for Davco Farming were:

|

|

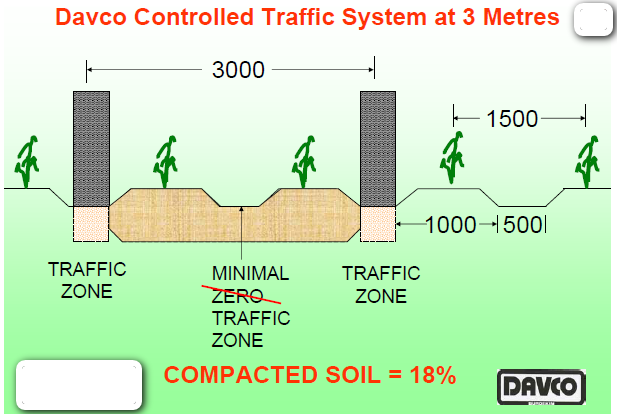

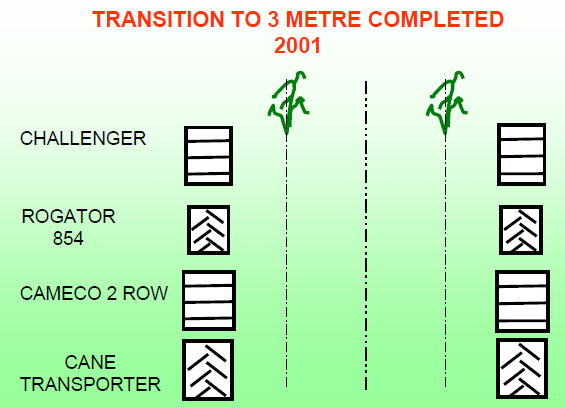

Davco 3m Controlled Traffic Farming System

Davco Farming has developed a 3 metre Control Traffic (CT) farming system for sugarcane production as described below. System Features

NOTE: The Davco Control Traffic System at 3m requires a harvester with wheel/track spacing at 3m. The CAMECO double row harvester met this requirement however there is currently no suitable commercially available harvester. Davco Farming is currently redesigning the control traffic system with a reduced spacing to accomodate this constraint.

|

|

System Benefits

|

System Disadvantages

- Requires high accuracy GPS (+/-20mm) on multiple pieces of equipment

- May require a comprimise on planting depth

|

Field Operations

All field operations adhere to the control traffic system including:

|

|

Precision GPS Guidance

All machines used in the field (except cane transporters) have 2cm RTK guidance with automatic steering. This ensures a repeatable and accurate control traffic zone along with the many other precision guidance benefits. |

|

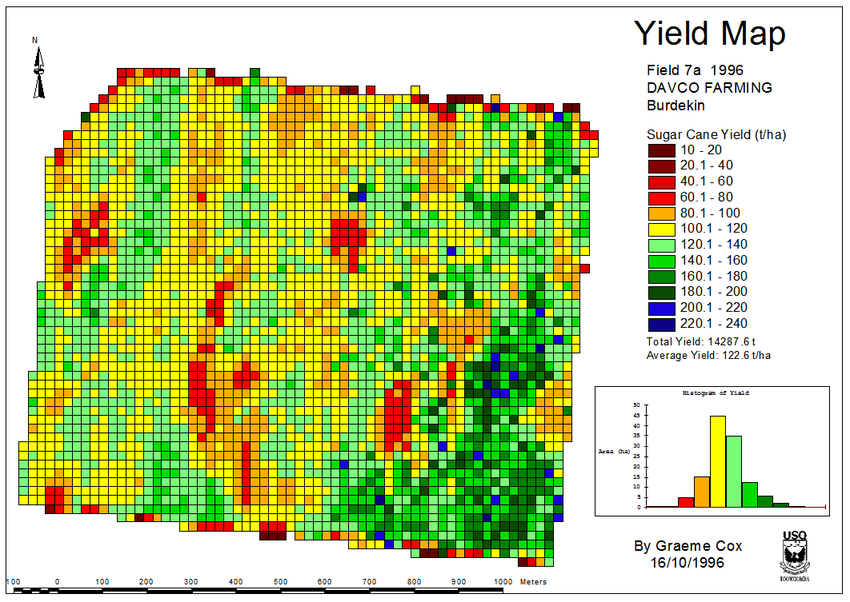

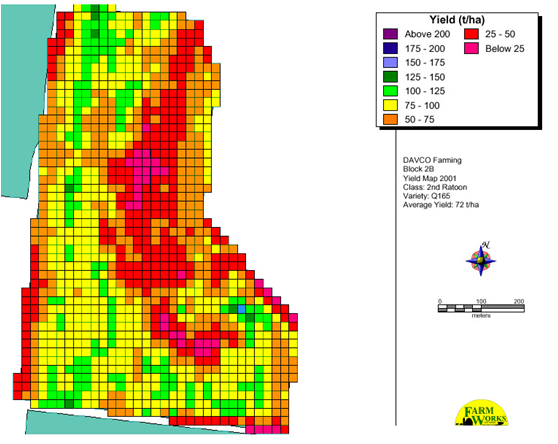

Yield Mapping

Yield mapping is an essential part of precision agriculture. Yield maps provide essential information for the spatial analysis and evaluation of crop production management at a within field level. In 1996, Dr Graeme Cox produced the worlds first yield map of sugarcane using data from a mass flow sensor in the harvester and GPS information. This map is shown below. This research was partially funded by Davco Farming and eventually gained Graeme his PhD. The results of this work are provided in the 'Publications' section of this website. Davco Farming has yield mapped ever since and the yield maps are used to support decision making, primarily in guiding variable rate application of gypsum. |

Variable Rate Application

Variable rate application is the application of a crop input at differening rates across a field. Davco Farming experiences significant variablility in crop yield, primarily due to differences in water infiltration rates of soils. Low yields are generally found in areas with low infiltration rates caused by high sodicity, resulting is reduced soil water in the root zone. In fact, soil testing has shown that up to 85% of the yield variability in the yield map shown above, could be attributed to the levels of soil sodicity and magnesium.

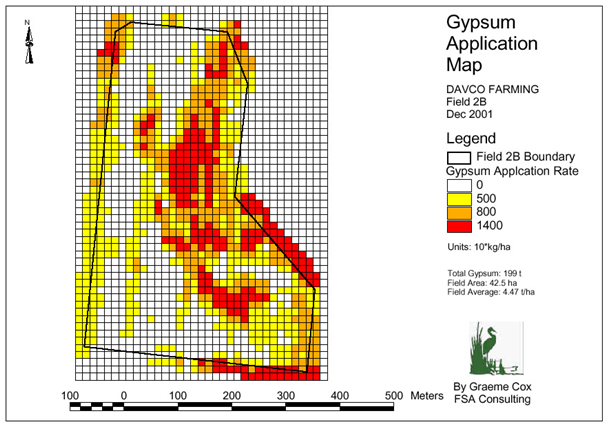

A solution to this is to apply gypsum a rates up to 20t/ha but this is expensive (up to $2200/ha) and also can be detrimental to soils that already have good infiltration rates, resulting in excess infiltration which can lead to rising groundwater levels and salinity. Therefore variable rate application of gypsum is highly benificial. The maps below show how the yield maps are used directly to create variable rate gypsum applicaton maps.

Variable rate application is the application of a crop input at differening rates across a field. Davco Farming experiences significant variablility in crop yield, primarily due to differences in water infiltration rates of soils. Low yields are generally found in areas with low infiltration rates caused by high sodicity, resulting is reduced soil water in the root zone. In fact, soil testing has shown that up to 85% of the yield variability in the yield map shown above, could be attributed to the levels of soil sodicity and magnesium.

A solution to this is to apply gypsum a rates up to 20t/ha but this is expensive (up to $2200/ha) and also can be detrimental to soils that already have good infiltration rates, resulting in excess infiltration which can lead to rising groundwater levels and salinity. Therefore variable rate application of gypsum is highly benificial. The maps below show how the yield maps are used directly to create variable rate gypsum applicaton maps.

|

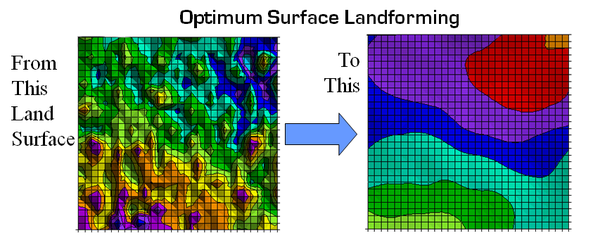

Optimum Surface Landforming

OptiSurface Landforming uses 3D machine control (GPS or GPS & Laser) and smooth 3 dimensional design surfaces to offer the ultimate surface drainage solution with minimal soil movement. Advantages over traditional laser based landforming:

In the figure below, the map on left is natural topography with depressions. The map on the right is the topography after OptiSurface landforming. Davco Farming is actively developing and using this technology in the development of a new sugarcane farm, 'Oaky'. |

|

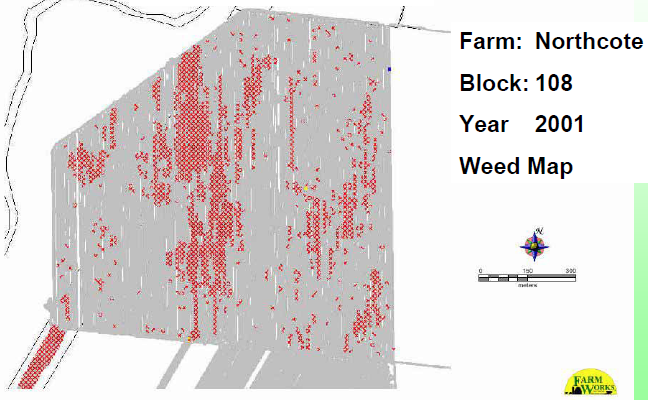

Weed Mapping

Weed mapping is carried out by tractor operators during normal field operations. The location of problem weeds that are not killed by broad spectrum herbicides such as nut grass and sorghum are logged. The data is collected and the maps are then produced and used to navigate back to spray the weeds. |